Keck Quality control

The KECK rifle scope has undergone rigorous testing that meets international standards, demonstrating exceptional resistance to impact, corrosion, extreme temperatures, water, dust, and fog. Whether in extreme climates, prolonged transport, or under the powerful recoil of large-caliber firearms, the KECK scope maintains high stability and precision. Its optical system and structure remain undamaged in high-stress environments, providing reliable tactical support for shooters. With strict quality standards and outstanding craftsmanship, the KECK scope is a trusted partner in the most challenging conditions.

1. Shock Test – Extreme Endurance

Test Steps:

- Shock Testing Equipment: Using a professional shock testing machine to simulate recoil and external impacts similar to real shooting scenarios.

- Test Process: Each KECK scope undergoes 1,000 cycles of 1,000Gshock testing. After each test, the aim point deviation is recorded to ensure the stability of the optical system and structure.

Test Results:

- After 1,000 shocks, the KECK scope maintains accuracy within ≤1 MOAat a distance of 100 yards, meaning minimal deviation even under high-intensity impact, ensuring shooting precision.

Comparison with Industry Standards: The KECK scope meets the MIL-STD-810G shock testing standard, a globally recognized standard for the durability of military equipment under extreme conditions. In contrast, many standard consumer-grade scopes cannot pass such stringent testing.

2. Salt Spray Test – Long-Lasting Corrosion Resistance, All-Weather Reliability

Test Steps:

- Salt Spray Test Equipment: A specialized salt spray chamber simulates humid, saline, and other corrosive environments.

- Test Process: The KECK scope is exposed to a 5% saltwater solution for 500 hours. The scope’s exterior and internal components are regularly inspected for signs of corrosion or rust.

Test Results:

- Even after prolonged exposure, the KECK scope’s metal surface remains smooth, with no signs of corrosion. This indicates that KECK scopes maintain performance in extreme humid and saline environments.

User Experience: “I used the KECK scope in humid conditions, and it performed flawlessly. The exterior showed no corrosion, and the lens remained clear.” – Outdoor hunter feedback.

3. Vibration Test – Stable Precision, Ideal for Long-Distance Transport

Test Steps:

- Vibration Test Equipment: A standard vibration table simulates the shaking and vibrations experienced during long-distance transport or intense tactical movements.

- Test Process: The KECK scope undergoes vibration testing for 1-1.5 hoursacross a range of frequencies, from low to high, covering a comprehensive range of vibration environments.

Test Results:

- After vibration testing, the KECK scope’s optical and mechanical structure remains intact, with no displacements or loosened components, ensuring reliability during transport or in unstable environments.

4. Drop Test – Precise After Accidental Falls

Test Steps:

- Test Process: The KECK scope is dropped multiple times from heights of 3 to 6 feetonto a concrete surface to simulate potential accidental drops during use.

Test Results:

- The KECK scope remains fully functional after drops, with no damage to the optical system and no deviation in aim point accuracy, ensuring durability in rugged conditions.

Customer Feedback: “During an outing, my KECK scope accidentally fell onto rocks, and to my surprise, it remained completely intact, with perfect accuracy.” – User feedback from Jack.

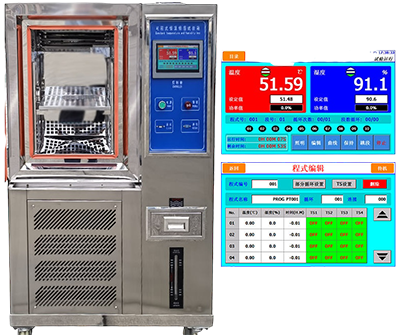

5. Temperature Test – Performs Flawlessly in Heat and Cold

Test Steps:

- Temperature Test Equipment: High and low-temperature environment chambers.

- Test Process: The KECK scope is exposed to temperatures from -30°C to 40°Cfor 48 hours, testing the stability of its optical and mechanical systems in extreme conditions.

Test Results:

- In both high and low temperatures, the KECK scope’s optical system remains clear and stable, with no deformation or damage to the mechanical structure, ensuring reliable performance in extreme climates.

Application of Industry Standards: The KECK scope meets MIL-STD-810G temperature testing standards, which are widely used to verify the reliability of military equipment under extreme climate conditions, exceeding consumer-grade standards.

6. Rapid Temperature Change Test – Clear Optics Without Condensation

Test Steps:

- Test Process: The KECK scope is rapidly cycled between 40°Cand -30°C environments for 10 cycles to observe for any condensation or structural failure.

Test Results:

- After rapid temperature changes, the KECK scope’s optical system remains clear with no fogging, ensuring a stable view even in environments with sudden temperature shifts.

7. Waterproof Test – Outstanding Waterproof Performance for All Weather Conditions

Test Steps:

- Test Process: The KECK scope is submerged to a depth of 5 metersfor 30 minutes and then inspected for internal water ingress and waterproof performance.

Test Results:

- The KECK scope meets the IPX7 waterproof standard, with no water ingress or damage after immersion, ensuring reliable performance in rain or accidental water exposure.

8. Sealing Test – Dustproof and Fogproof for Any Climate

Test Steps:

- Test Process: The KECK scope utilizes O-ring sealsand nitrogen purging and undergoes rigorous sealing tests to ensure internal optical components remain unaffected by dust or moisture.

Test Results:

- Even in high-dust environments, the KECK scope retains its dustproof and fogproof features, ensuring stability for long-term use.

KECK Rifle Scope – Mold Resistance Test

To ensure the reliability of the KECK rifle scope in humid and high-moisture environments, we conducted a rigorous mold resistance test to verify its anti-fungal performance. This test adheres to industry standards and simulates tropical and subtropical high-humidity conditions, ensuring the scope remains unaffected by mold during prolonged use.

Mold Test Procedures:

Test Environment: The KECK scope was placed in a specialized mold incubation chamber with humidity levels maintained above 95% and a temperature between 28°C and 30°C. The environment was densely populated with mold spores.

Test Process: The KECK scope was exposed to high humidity and high temperatures for 28 days, with regular observations to check for any mold growth or signs of corrosion on the exterior and internal optical components.

Surface Treatment: The KECK scope underwent anti-mold treatment prior to testing, ensuring that its surface materials and sealing structure resist mold growth, even in persistently damp environments.

Test Results:

- Strong Mold Resistance: After 28 days of high-humidity exposure, there were no signs of mold on the KECK scope’s exterior, lenses, or internal optical system.

- Optical Performance Maintained: The scope’s clarity and brightness remained unaffected by the humid conditions, proving its reliability in challenging climates.

Conclusion:

The KECK rifle scope excelled in mold resistance testing, demonstrating its durability in humid environments. Whether in tropical rainforests or other damp regions, the KECK scope maintains clear optics and stable performance, providing shooters with dependable support in all conditions.